Rubber gaskets

Rubber gaskets

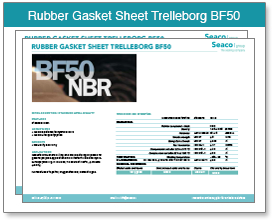

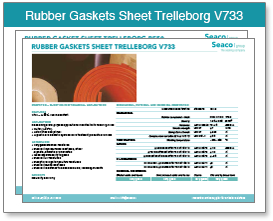

Rubber is the major and most commonly used material for sealing products and works within a temperature range of -50 ⁰C to +120 ⁰C. Rubber comes in many forms and can be found in many products. Seaco Group BV concentrates mainly on rubber flange gaskets, manhole gaskets, cover gaskets and O-rings. The latter will be dealt with separately, because it’s the largest group of rubber gaskets. Rubber’s most important property is that it reverts to its original shape once relieved of pressure. This elasticity means that it is ideally suited as a sealing material. Rubber gaskets can be used in a diversity of applications, as long as these are within a set range of temperatures and have medium resistance. Both can have a lasting and detrimental effect on rubber.

Materials and designs

Commonly used materials include: EPDM, which has excellent ozone- and UV-resistant qualities. CR-Neoprene, which is self-extinguishing, hardly ages and can resist acids. NBR (Nitrile) which shows good resistance to oil, petrol and certain solvents. VMQ (silicone), which offers excellent flexibility at low temperatures. FKM (Viton) which has the best chemical resistance of any type of rubber. CSM (Hypalon), which shows good resistance to acids, lyes and can also cope with high temperatures.

Rubber gaskets can also come with or without woven inlays for reinforcement. Depending on the application, the rubber can incorporate 1 or even more inlays to create a strong and hard-wearing seal. Of course, its resistance to wear also depends on the type of rubber used and its hardness.

Applications

The water industry is one of the many industries that uses this kind of sealant. EPDM sealants are commonly used where drinking water is used. NBR is often used as a sealant for gas, but also for applications in industries where oils and fats are used. A great diversity of rubber sealants can also be found in the manufacturing industry (OEM), mainly because of the wide number of applications involved.

Rubber Gaskets for vibration control

O-rings

O-rings represent the largest group with the category of rubber gaskets. It’s simply impossible to keep all O-rings in stock, so Seaco Group BV has matched up its range of products to suit its customers’ needs. Seaco Group BV has all the necessary O-rings in stock for this group of users.

In general, O-rings can be subdivided into four categories which each reflect the type of application involved.

Static applications under pressure

Flange gaskets and cover gaskets are included in this category. Depending on the specific form of application, pressures of between 0 to 1000 bar can be expected. For high pressures, use will be made of sealing chambers to prevent a blowout.

Static applications in a vacuum environment

Much is demanded of the O-ring for these kinds of applications, specifically the precision of the groove. The ring must fill the whole of the groove, for example. This is where choosing the right material comes into its own. We are only too glad to help you make the right choices in such situations.

Dynamic axial (reciprocating) applications

These applications are most common in hydraulic and pneumatic cylinders. The choice of O-ring and the material depends on the specific application (pressure, speed of movement, medium, temperature patterns, surface stability, etc.)

Rotating and vibration-isolation applications

O-rings are ideal for these applications. For example: valve stems, rudder and propeller movement, rotating axles, etc. However, the scope of applications is limited. This is primarily because of the space left over to fit the ring(s). The speed of rotation must not be above 5 m/s.

Materials

O-rings are available in a variety of different materials. The most common materials for these are the following: NBR, EPDM, FKM (Viton), PTFE and Kalrez.

Applications for rubber gaskets

The water industry is one of the many industries that uses this kind of sealant. EPDM sealants are commonly used where drinking water is used. NBR is often used as a sealant for gas, but also for applications in industries where oils and fats are used. A great diversity of rubber sealants can also be found in the manufacturing industry (OEM), mainly because of the wide number of applications involved. O-rings are extremely versatile in a wide number of markets, including the manufacturing industry (OEM), the (petro-)chemical industry, heat installations and in hydraulic and pneumatic settings.

Given the huge diversity of sizes and designs, the recommendation is to pick a standard size to keep this as simple as possible.

If you’d like to know what O-ring is the most suitable for your applications, just get in contact with us. We’re happy to be of assistance. Info@seaco.eu or call +31 (0)10 – 522 65 36. You can also download our data sheet.